Steadily growing as a leader in precision grinding industry in Japan

Since its founding, KSK (Kawasaki Seiki Kosakusho,Co.,Ltd.) has been providing to our customers a wide variety of precision products of the highest quality by using our latest technologies and machinery. As a result, KSK has grown to become a leading precision grinding company in Japan. We now have established customers not only in Japan, but also worldwide.

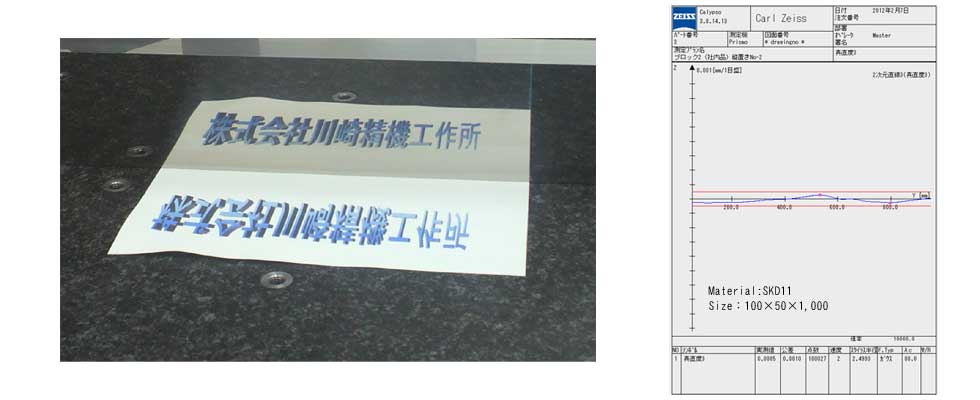

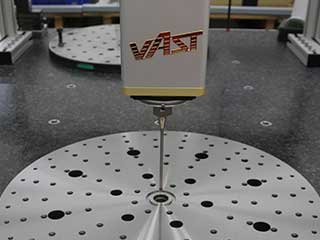

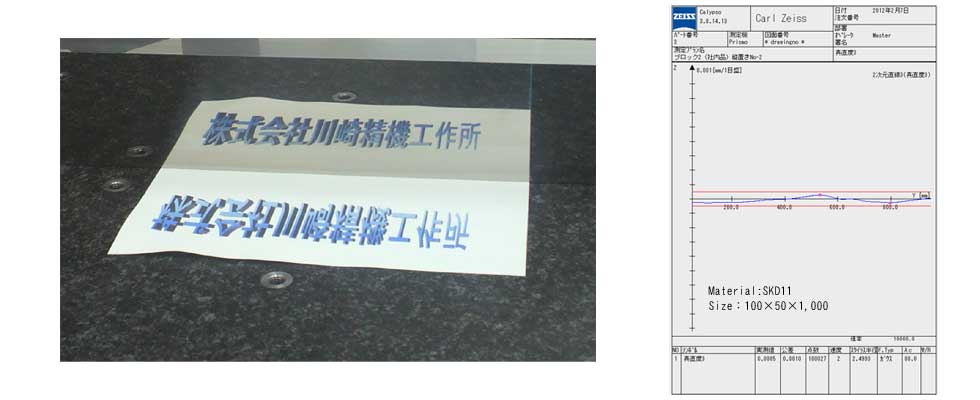

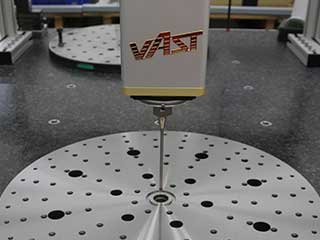

In order to meet world market requirements in the 21st century, KSK has raised the standard of quality assurance to a degree of accuracy measured in sub-microns, by installing CNC Coordinate Measuring Machine made by Carl Zeiss and other technologically advanced equipment. At present through continuous improvement we take great pride in manufacturing precision products that you designing your drawing by using various machines and equipments.

We look forward to serving you in the near future.

The best, consistent precision grinding technology utilizing latest equipment by highly trained professionals.

KSK (Kawasaki Seiki Kosakusho,Co.,Ltd.) has very modern, efficient manufacturing equipment and dedicated, highly trained professionals. That enables us to manufacture super-high precision grinding products and to meet our customers' high-quality requirements, which vary in a wide range of materials and sizes.

KSK's customers, most of which are listed on the Tokyo Stock Market, come from various industries. We have been supplying parts and components to machine tool industry, steel industry, ship-building and aircraft industry in Japan over the past few decades. Recently we have been seeing more demand from the information technology industry and are enjoying good reputation for our products in the field of semiconductor processing equipment and cast-metal products for laser disc.

We have a growing number of customers in the field of semiconductor processing and cast-metal for laser disc. At KSK, we strive to supply highly precise products in any material such as aluminum, stainless steel, etc. We can also process products in any form such as raw material, cast-metal products, etc.

KSK maintains the latest and most reliable grinding technologies. For example, we use a high-speed machining center whose main axis rotates as fast as at 20,000RPM. With such technologies and our dedicated skills over the years, we are trying to ensure fast delivery and high quality to satisfy any customer's requirements.